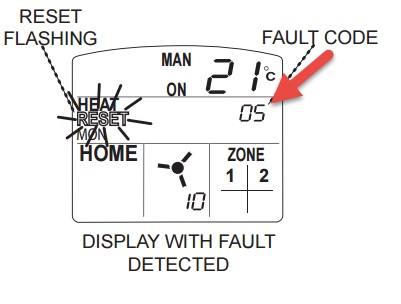

The Braemar controller (Spectrolink & Magiqtouch) thermostat control not only operates your heating system but also monitors and controls all its functions. If the system encounters any issues during operation, the Braemar controller will display an error code symbol (A Spanner) on its screen.

Experiencing issues with your system? Before calling for service, try a simple reboot first. Unplug the unit from the power plug or turn off the main power switch from your switchboard for at least 5 – 10 minutes. This can often resolve minor glitches.

If the problem persists and the error code doesnt go away, Don’t hesitate to call us on 0411 792 669 – 24/7 Emergency On Call

Fault:

PS Low closed at start

Description:

The ICS has detected that the low pressure switch is already closed prior to starting the

combustion fan

Fault:

PS Low failed to close

Description:

After powering the combustion fan the ICS has detected that the low pressure switch failed to close within the required time

Fault:

PS Low opened during run

Description:

The ICS has detected the low pressure switch open during run

Fault:

Thermistor > 70° during run

Description:

The ICS has detected the thermistor temperature above 70° during run

Fault:

Thermistor short or open circuit

Description:

The ICS has detected the thermistor as out of range

Fault:

Flame detected when not required

Description:

The ICS has detected a flame signal when it isn’t required

Fault:

Ignition Failure

Description:

The heater has failed to detect a flame within the specified time period

Fault:

PS Condensate closed at start

Description:

The ICS has detected the condensate pressure switch is already closed before the start cycle

Fault:

Thermistor > 60°C during start

Description:

The ICS has detected that the thermistor is above 60° during its start cycle

Fault:

HX OT1 Open

Description:

The ICS has detected the HX OT1 over temperature circuit has opened

Fault:

Loss of flame signal

Description:

The ICS has detected a loss of flame signal on the flame sensing circuit

Fault:

PS High closed at start

Description:

The ICS has detected the high pressure switch as being already closed during start up

Fault:

PS High failed to close

Description:

The ICS has detected that the high pressure switch has failed to close within the set time limit

Fault:

PS High opened during run

Description:

The ICS has detected the high pressure switch as open while the heater is running

Fault:

Thermistor in cool duct location

Description:

The ICS has had multiple over temperature OT1 resets from the thermistor not telling the ICS to increase fan speed

Fault:

Thermistor in cool duct location

Description:

The ICS has had multiple over temperature OT1 resets from the thermistor not telling the ICS to increase fan speed

Fault:

Condensate detected during run

Description:

The ICS has detected the condensate pressure switch as open during run

Fault:

Condensate detected during start

Description:

The ICS has detected condensate in the heat exchanger drain pan during start cycle

Fault:

HX OT2 Open

Description:

The ICS has detected the secondary over temperature circuit as being open. It will cut power to the gas valve and increase fan to maximum speed

Fault:

Flame roll-out detected during start

Description:

The ICS has detected a flame roll out condition during the startup cycle

Fault:

Flame roll-out detected during run

Description:

The ICS has detected a flame roll out condition during the run cycle

Fault:

Supply voltage out of range

Description:

The ICS has detected the supply voltage or the transformer voltage is out of acceptable limits

Fault:

Room fan not running

Description:

The room fan hasn’t reached 200rpm within the first 10 seconds of starting

Fault:

Room fan running backwards

Description:

The motor speed sensor has detected the room fan running backwards

Fault:

Data table FLAG incorrect

Description:

The ICS has found an error in the data tables

Fault:

Loom ID incorrect

Description:

The wiring loom installed does not match the heater model

Fault:

Combustion air pressure detected prior to start

Description:

The ICS has detected air pressure on the pressure sensor before starting its start cycle

Fault:

Combustion air pressure too low at start

Description:

The combustion air sensor is not sensing enough air pressure during the start cycle

Fault:

Gas relay high error

Description:

The ICS has detected and error with the high gas relay

Fault:

Gas relay low error

Description:

The ICS has detected an error with the low gas relay

Fault:

Flame roll out circuit check failed

Description:

The flame roll out has failed its circuit check

Fault:

Flame roll out loom not attached or short circuit to ground

Description:

The ICS has detected that the flame roll out circuit is either disconnect or has a short

circuit

Fault:

Reset button stuck

Description:

The ICS has detected the reset button as being jammed down or stuck closed

Fault:

Gas valve closed during run

Description:

One or both of the ICS gas valve relays opened unexpectedly while the heater was running

Fault:

Combustion air pressure sensor error

Description:

The ICS has detected an error with the air pressure sensor

Fault:

Combustion air pressure too low during run

Description:

The ICS pressure sensor has lost pressure during run

Fault:

Gas valve modulating coil outside range

Description:

The ICS has detected the modulating coil on the gas valve is outside of the allowed range

Fault:

Combustion pressure sensor communication error

Description:

The ICS has detected a communication error with the air pressure sensor

Fault:

Micro flame mismatch

Description:

The ICS has detected a mismatch between the microprocessors

Fault:

5 lockouts within 15 minutes

Description:

The ICS has locked out 5 times within a 15 minute time frame

Fault:

MagIQtouch controller communication loss

Description:

The ICS has lost communication to the MagIQtouch control after 5-10s it will turn off the call

for heat

Fault:

Micro 2 error found

Description:

The ICS has detected an error on the second microprocessor

Fault:

System check memory error

Description:

The ICS had detected an error while checking the system memory

Faut:

Voltage Rail Error

Description:

The ICS has detected an error on the voltage rail

Fault:

ICS Fault

Description:

The ICS has detected an internal error

Fault:

Micro one reading 1 at start up

Description:

The ICS has detected a flame sense reading above its threshold

Fault:

Micro one reading 2 at start up

Description:

The ICS has detected a flame sense reading above its threshold

Fault:

ICS flame circuit error – Micro 2

Description:

The ICS has detected an error with the second microprocessor on start up

Fault:

Ripple value too high at start up

Description:

The ICS has detected a flame sense reading above its threshold

Fault:

Micro one reading 1 after pre purge

Description:

The ICS has detected a flame sense reading above its threshold

Fault Code:

Micro one reading 2 after pre purge

Description:

The ICS has detected a flame sense reading above its threshold

Fault:

ICS flame circuit error – Micro 2

Description:

The ICS has detected an error with the second microprocessor after pre purge

Fault:

Ripple value too high after pre purge

Description:

The ICS has detected a flame sense reading above its threshold

Fault:

Micro one reading 1 during start up

Description:

The ICS has detected a flame sense reading above its threshold